What is Remanufacturing and Why It’s Changing the Global Machinery Market

What is Remanufacturing and Why It is Changing the Global Machinery Market

In today's global machinery and automotive industry, there is growing interest in the term “remanufacturing.” Rather than being just a cost-saving solution, it is a sustainable business model. But what precisely is remanufacturing, and how does it differ from repair or refurbishment?

1. Definition of Remanufacturing

Remanufacturing involves the complete disassembly and inspection, replacement of key components, reassembly, and testing of used equipment or parts such as engines, gearboxes, and axles to bring them up to like-new performance and appearance standards.

Simply put, remanufactured products are not just “fixed”; they are rebuilt to perform almost like new.

2. Remanufacturing vs. Refurbishment vs. Repair

| Comparison | Remanufacturing | Refurbishment | Repair |

|---|---|---|---|

| Disassembly | Complete | Partial | Minimal |

| Component Replacement | All critical components | Partial | Only damaged parts |

| Performance Standard | Up to new | Improved condition | Basic functionality |

| Testing | Strict & systematic | Simple tests | Basic inspection |

| Appearance | Almost new | Improved | Not a priority |

Note: Remanufactured products often achieve 80%-95% of new product life and reliability at 50%-70% of the cost of a new product.

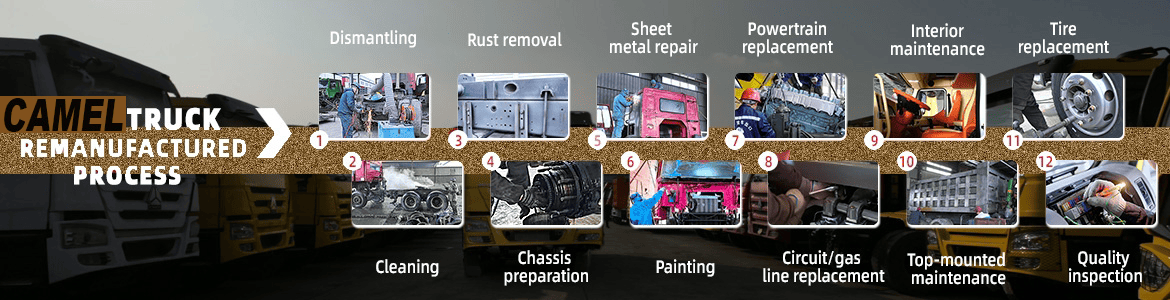

3. Typical Remanufacturing Process

Core Collection

Collect used or end-of-life equipment as raw material.Disassembly & Cleaning

Completely disassemble and remove oil, rust, and debris.Inspection & Grading

Check each part for wear and decide which can be reused and which must be replaced.Replacement of Key Components

Replace worn or outdated parts with new ones.Reassembly

Reassemble to the highest possible standards.Performance Testing

Carry out comprehensive power, sealing, noise, and other functional tests.Painting & Packaging

Restore appearance and prepare for delivery.

4. Benefits of Remanufacturing

Cost Savings – Typically 30%-50% lower than new equipment.

Environmentally Friendly – Reduces raw material consumption and carbon footprint.

Reliable Performance – Meets international standards and rigorous testing.

Shorter Lead Times – Faster delivery than manufacturing new products.

Warranty & Support – Many suppliers provide warranties similar to new products.

5. Applications in Trucks and Construction Machinery

In the truck industry, remanufacturing is usually applied to:

Engines

Gearboxes

Axles / Differentials

Hydraulic systems

For example, a remanufactured engine may have its cylinder liners, pistons, crankshaft, bearings, seals, and injectors replaced, and then tested on a dynamometer to achieve near-new performance.

6. The Future of Remanufacturing

With increasing environmental regulations and cost pressures, remanufacturing is moving from a “backup solution” to a mainstream practice.

In Europe and the U.S., companies such as Caterpillar, Volvo, and Cummins already have mature remanufacturing systems.

In China, major truck and machinery manufacturers like Sinotruk and Weichai Power are rapidly expanding their global remanufacturing offerings.

7. Conclusion

Remanufacturing is not just “reusing old machines”; it is an advanced manufacturing solution that combines technology, sustainability, and economic value.

Customers can benefit from:

Affordable pricing

Near-new performance

A greener supply chain

For businesses involved in machinery, trucks, or parts exportation, remanufactured products are a high-value option worth promoting.