Shacman Used Dump Truck F3000 Series

Rugged 8×4 platform: To the high-strength ladder frame and hub-reduction rear axles, and heavy weights, they built for rough haul roads.

Proven powertrain: Weichai engine + FAST manual gearbox for a strong low-speed pull and also easy, low-cost servicing.

Work-matched bodies: Earth (8/6 mm) or rock (12/10 mm) boxes, liners optional—spec to your material and law legal gross.

Faster cycles: Front-lift hydraulic hoist and reinforced tailgate for quick, clean dumps, and less carryback.

Fleet friendly: HW-series cab comfort, widely available parts, and simple maintenance all combining to minimize downtime and make cost per ton low.

Contact Rory Now For A No Obligation Quote Via WhatsApp Talking!

If your project needs a sturdy, economically driven tipper, the Shacman F3000 Series is the perfect solution. This 8x4 truck is designed to accommodate a large payload and comes with a strong chassis, trusted Weichai engine, and tough steel container. It is the kind of truck that a fleet would select when they require easy maintenance, consistent supply of spare parts, and a cab that drivers are comfortable in for long working hours. The F3000 is a reliable source of customized dump trucks for the buyers who want uniformity in fleets and site installations that suit the actual terrain—and that is precisely the reason the F3000 has become a common choice in mining, quarrying, and large civil projects.

The F3000 is a Machine That Performs in the Real World.

No matter what, it is still a truck designed for heavy loads. The F3000’s rough-and-tumble ladder frame is built with heavy-duty steel rails along with cold-riveted cross members that can withstand twists on uneven roads of mine. Each axle has multi-leaf springs plus heavy-duty pins to share loads equally, thus allowing the truck to maintain its cool when one end of the truck goes down into a hole. Besides, the box options for the truck are—the earth build and the rock build—so you can choose the thickness of the side plates based on the material that you are using mostly, which is the first rule of designing custom dump trucks that last.

Power and gearing are just right together. The low-speed torque of Weichai provides good pulling power together with the fast movement that makes the truck move easily from the face to the hopper and back again. The spacing of the ratio is such that it is easy to control when going uphill and not just for the sake of impressing with numbers in the brochure. That is the reason why the F3000 sometimes becomes the core of the fleets that do standardization of custom dump trucks by axle ratio and tire set for each site.

Less time spent at the tip. A high-pressure front hoist provides a very nice and stable lifting up. Loads that tend to stick are less likely to do so. Do not have to rock the bed very often. If your operation measures productivity in terms of cycles per hour, it is here that the custom dump trucks make their biggest contributions—applied for longest box, highest side, and most protective liner, thus perfectly tuned to your density and drop height.

Driver comfort factor equals constant output. The flat-top cab has remarkable ergonomics: a supportive seat, an efficient air conditioning system, clear instruments, and good visibility. It is not extravagant, but drivers get through a long rotation without getting tired. For custom dump trucks that are ordered in bulk, having the same cab layout across all units helps in cutting down the training and minimizing the errors when the crew swapping the vehicles during the shift.

The parts are in the places where you need them. Filters, brake wear items, belts, lamps, and common hydraulics are not difficult to get in Southeast Asia, Africa, the Middle East, and South America. This availability is one of the major reasons why customers are willing to have dump trucks with F3000 chassis that are custom-made instead of relying on a mix of orphan models.

Use Cases That Match the F3000

l Hauling in open-pit mines and quarries: Moves of overburden, ore, and aggregate between the face, crusher, and stockpile.

l Civil works of massive scale: Making highway embankments, creating platforms, building dams, and levees.

l Urban digging and muck-away: Transferring materials on private haul roads with frequent gate crossings.

l Plant logistics: Quick transfers in crushing/screening yards and port stacks.

Configuration Approach: Think Like an Owner

In case your KPI is cost per ton and timely delivery, the most intelligent method of acquiring the F3000 is to consider it as a foundation for personalized custom dump trucks. Let's start with three facts:

1. Material is the supreme ruler. Sand and soil allow 8/6 mm floor/sides for lower tare, blasted rock frequently demands 12/10 mm and a liner.

2. Ramps are the determining factors for ratios. Steep benches and soft underfoot conditions need conservative finals with hub-reduction rears. On the contrary, flatter routes can afford to lose a little torque for lower revs.

3. Tyres are the key to availability. 13R22.5 is readily available and very sturdy, having a common size for custom dump trucks helps in terms of spares and rotations.

Product Story (How It Performs Throughout the Shift)

Morning mist, wet track, and loaders lined up: the F3000 with its gradual and calm launch, becomes the protagonist without the noise of a drama. The chassis remains level through the first corner while the left side wheels get into the ruts from the previous day. The driver gets accustomed to the ratios and does not search for gears. The front hoist at the hopper goes up steadily with no sway—tailboard unblocking, aggregate sliding, no need for a second bounce. Back props under the loader, the cycle repeats. This minute-to-minute behavior is the reason why operations teams choose this chassis to be the basis of their custom dump truck fleet: predictable, forgiving, and fast to serve at the end of the day.

Features That Are Important on Site

l High-strength frame: Resists torsion and maintains the right driveline angles during shock loads.

l Heavy-duty axles: Front and rear with hub-reduction durability of HANDE and MAN-pattern respectively.

l FAST gearbox: The shift feeling is clean, and manufacturers are familiar with it in most markets.

l Hydraulic hoist: Slow up and down, stable lift on the centerline, and less “carryback.”

l Cab comfort: A/C that really works, driver seat that is welcoming, and user-friendly switchgear.

These features are the building blocks of custom dump trucks that after the first hard season still hold value.

Specifications

Item | Specification |

Model | SX3315DU406 |

Driver position | Left-hand drive |

Driving type | 8×4 |

Wheelbase | 1800 + 3975 + 1400 mm |

Max speed | 75 km/h |

Engine (popular options) | Weichai WP12.430E201 (430 hp), Euro II/III; optional WP12.400E201 (400 hp) |

Transmission | FAST 10JSD180 + QH50 (manual) |

Front axle | HANDE MAN 9.5T |

Rear axle | HANDE 16T MAN, hub-reduction |

Final drive ratio | 5.92 (other ratios available by market) |

Clutch | Ø430 diaphragm clutch |

Steering | ZF technology |

Frame | 850 × 300 (8 + 7) high-strength ladder frame |

Suspension | Front/rear multi-leaf springs; four main plates + four saddle bolts |

Fuel tank | 380 L (long-haul options available) |

Wheels & tyres | 13R22.5, 12 + 1 spare |

Service brake | Dual-circuit compressed-air |

Parking brake | Spring-applied, air-released |

Auxiliary brake | Engine exhaust brake |

Cab | Medium length flat-top; hydraulic main seat; four-point hydraulic suspension; A/C; manual flip cab; steel bumper; 3-step ladder |

Electrical & protection | Oil-bath air filter; oil-pan guard; tail-light guards; 165 Ah maintenance-free battery; hazard lights; anti-theft fuel system & battery box |

Body (typical) | 7800 × 2300 × 1700 mm; floor 10 mm / sides 8 mm |

Tare & payload | Varies by body/tyres; confirm per unit |

Terms (reference) | T/T, 30% deposit; balance before ex-factory delivery |

Delivery (reference) | ~55 working days after advance payment |

Warranty | 12 months from B/L date |

Options and Upgrades

l Rock-liner pack: Plates that protect the machine from high-abrasion stones.

l Dust kit: Cyclone pre-filter, sealed breathers, and lateral exhaust routing.

l Lighting guards and bumpers: Heavy grille protection for lamps and frontal components.

l Cold-start aids: For high-altitude or winter sites

l Telematics pre-wire: GPS and tracking of idle time and fuel use.

l Fleet standardization: Custom dump trucks made with the same. Wheelbase, axle ratio, tyre, and body thickness for easy rotation and parts stocking.

Purchasing Order Guidance

First and foremost, define your material. In case the rock predominates, then ordering the 12/10 body and a liner is the right choice. If it is soil/sand, then go for 8/6 for less tare weight. That one decision will influence fuel consumption, hoist speed and maintenance on all custom dump trucks you purchase.

Be straightforward about the ramp. Set the axle ratio for the steepest loaded climb, not for the highway. A gentle climb is always better than hot brake and gearbox churn.

Determinate tyre size. Choose the size that is most commonly available in your region at reasonable prices. Standardize this size across custom dump trucks so that one spare fit all.

Protect the undercarriage. Oil pan and tank guards have already paid for themselves by the first time you avoid a tow.

A small parts kit should be kept. Filters, belts, bulbs, brake wear items, a couple of hoses, and hub seals keep trucks in the cycle during busy weeks.

After-sales and Support

Before shipping, you get photographs and a video tour of the specific unit. The third-party inspection can be organized, and the starter kit of consumables can be loaded into the cab. Upon arrival, a brief commissioning checklist—fluids, fasteners, hoist timing, brake balance—quickly gets the truck to work. For fleets deploying several custom dump trucks, specifications can be mirrored across the batch, so every unit works the same and crews do not have to learn the controls again.

What Are the Reasons That the F3000 Was Chosen as a Base for Custom Dump Trucks?

Because it reaches the practical center: robust chassis, reliable engine, simple hydraulic system, and a cab that keeps drivers focused on their work. You are not risking a project with delicate electronics or unavailable components. You are purchasing a base that can be enlarged or reduced to meet the very constraints that you are dealing with—gate widths, ramp grades, legal gross, and the density of the loads you transport. Custom dump trucks' real value is that they mirror your job, not the other way around.

You need to specify your preferred material dominance on-the road (rock or earth) and grade that engenders the highest load in the dump body, plus the body volume. We will suggest a mix of customized Shacman F3000 configurations and will provide quotations of matched dump trucks along with their respective matched-truck ratios, tyre sizes, and body-plate specifications. Yes, inspection sheets and walkaround video clips will come your way, along with FOB / CIF pricing to your closest port. The trucks land make-ready. Please contact Rory via WhatsApp or call us +86 183 0640 8493.

*Note: Final body volume, tare/payload, and emission tier vary by unit. For the truck you are being quoted, we provide confirmed build sheets and videos.

About Us / Camel Truck

Shandong Camel Truck Co., Ltd. is located in Liangshan, Shandong, China – the largest used truck trading hub in the world. Founded in August 2010, the company has nearly 300 employees, including over 200 professional technicians. Our modern factory covers 25,000 m² and features top-class production lines, with the capacity to stock, maintain, refurbish, and repair over 3,000 trucks annually.

We supply trucks and parts from brands including HOWO, Shacman, Volvo, Mercedes-Benz, Beiben, covering dump trucks, tractor trucks, semi-trailers, mixers, and specialized vehicles. Our one-stop services include inspection, transportation, customs clearance, and after-sales support. Our sales network spans Africa, Central Asia, Southeast Asia, and more than 50 countries. In 2024, our sales revenue reached 100 million USD.

Since our establishment, we have upheld the corporate spirit of "Integrity First, Quality First, Service First," leveraging local resources and policy support to become a leader in China’s used truck industry, building "CAMEL TRUCK" into a globally recognized brand for used trucks, new trailers, and parts.

Truck Refurbishment & Services

Mechanical Maintenance & Overhaul: Thoroughly inspect engines, gearboxes, and axles, replace oils and filters.

Exterior Refurbishment: Repaint chassis, body, cabin, and rims to restore new look.

Component Upgrade: Replace critical parts (battery, fuel tank, wiring, air system) and update the AC system.

Cabin Renewal: Install new seats, sleeper, dashboard, and interior for comfort.

Final Polishing: Wax before shipment for shiny, clean surface.

Engine Remanufacturing: Use advanced equipment for full inspection and performance testing with reports to ensure reliability.

On-time Delivery: Partner with international shipping lines and freight forwarders to ensure safe, timely delivery.

Applications

Mining Transport

Dump Truck: High load capacity for sand, gravel, and ore. Tractor Truck: Transport large mining equipment and materials.

Construction Sites

Dump Truck: Transport large volumes of earth and construction materials. Tractor Truck: Haul concrete mixers or construction supplies.

Logistics & Freight

Dump Truck: Short-distance or regional bulk material transport. Tractor Truck: Long-distance container or freight transport.

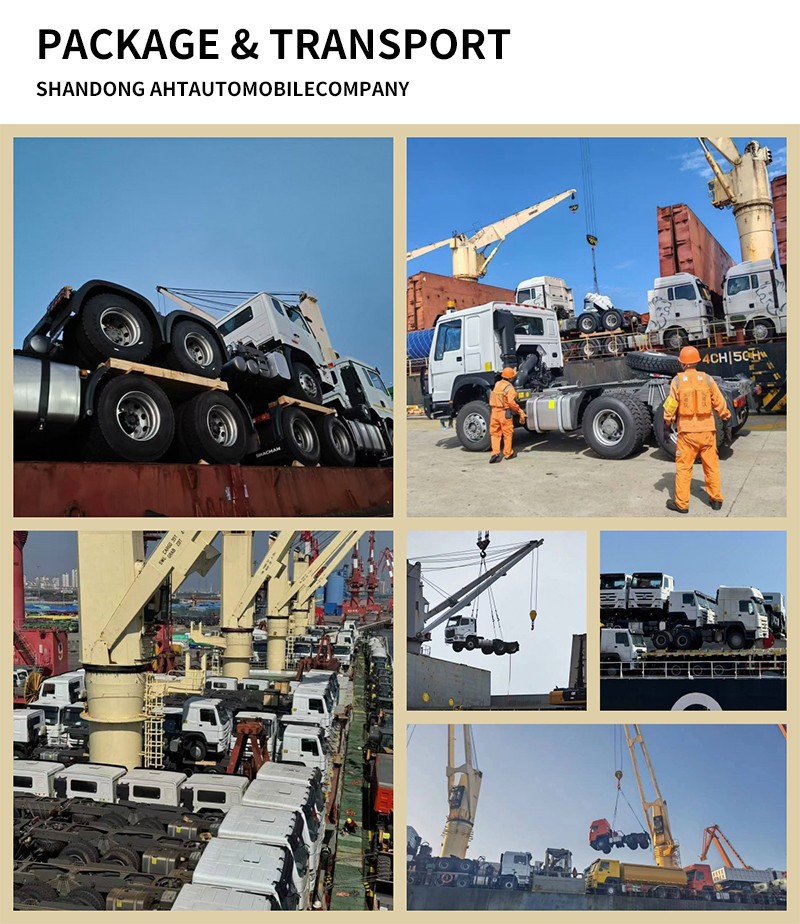

Port Shipping

We ship year-round from major ports including Qingdao, Tianjin, and Shanghai. All trucks are fully inspected and tested before shipping to ensure customers receive vehicles in excellent condition.

Certificates & Awards

Our company is ISO certified and has long-term partnerships with international logistics and mining companies, proving our export capabilities and industry recognition.

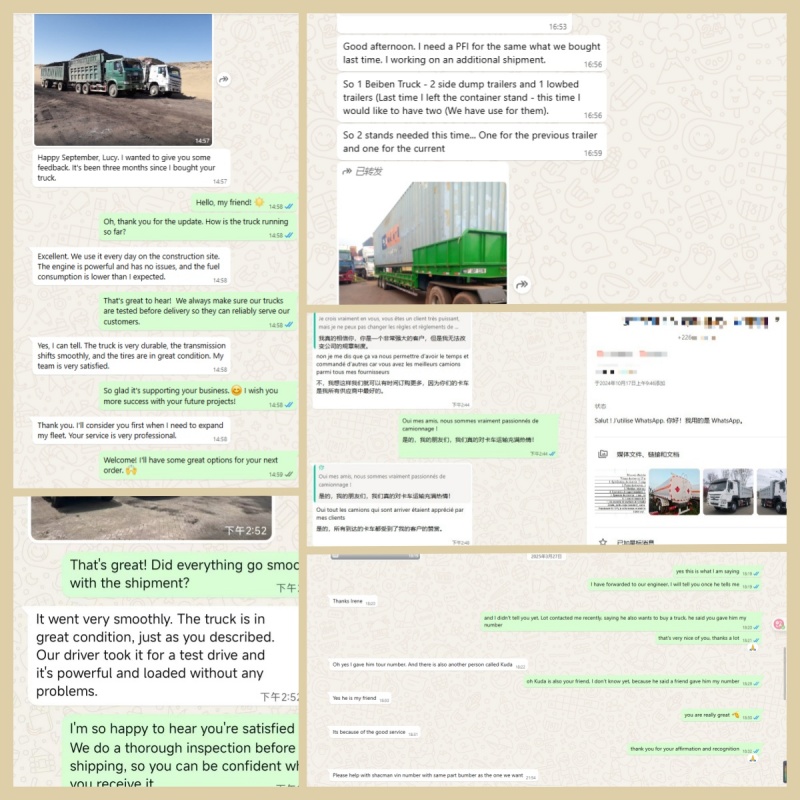

Customer Reviews

Below are authentic feedback from our customers. Our high-quality service has earned their trust, leading to long-term cooperation. Our professional design team also provides suitable customization plans and after-sales support, ensuring every customer receives excellent service.

Factory & Workshop

Our modern factory and workshop are equipped with advanced production lines and refurbishment facilities. We specialize in inspecting, maintaining, and refurbishing HOWO & Shacman dump trucks and tractor trucks, ensuring top-quality performance and reliability for all our vehicles.

Frequently Asked Questions

Q1: What payment methods do you accept?

A: We support T/T (30% deposit + 70% balance), L/C, and third-party escrow payments to ensure secure transactions.

Q2: How long does it take to ship?

A: Usually within 7–15 days after payment confirmation, depending on ports and shipping routes.

Q3: Do you provide warranty and after-sales service?

A: Basic warranty for engines and major components is provided. We also offer long-term OEM spare parts and remote technical guidance to ensure worry-free use.

Q4: Can we customize configurations?

A: Yes, we offer emission standards adjustment, cabin upgrades, tire selection, and other customization services. Contact our sales team for a quote.

Q5: What applications are dump trucks and tractor trucks suitable for?

A: Dump trucks are ideal for mines and construction sites, while tractor trucks are suitable for long-distance logistics, container transport, and heavy equipment hauling. Both are professionally refurbished for harsh conditions.