How Much Is a Dump Truck Load of Dirt?

If you are in the process of making a budget for your landscaping, grading or constructing projects, then a question may come up: How Much is a Dump Truck Load of Dirt? The short answer is: It depends on the volume, weight, soil types, transportation distance, local labor and fuel cost, etc. In this circumstance, we will analyze the truck loading capacity, pricing factors, local market, and handling tips respectively in this article so that you can get a precise total cost. In this way, everything will be ready on the delivery day.

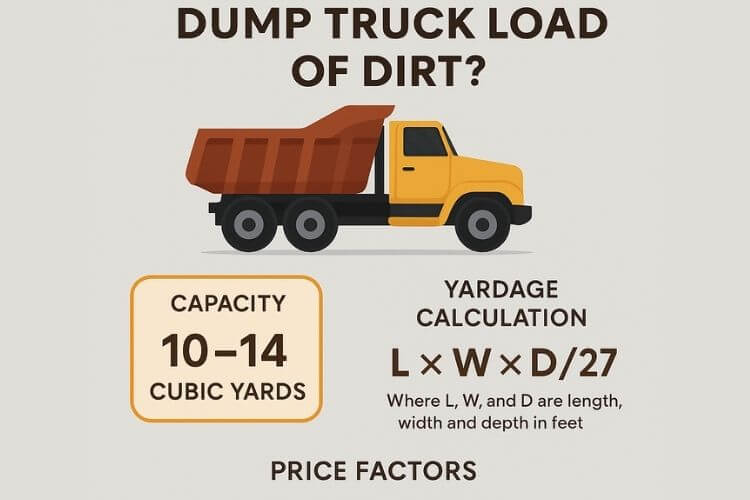

1. How Many Yards Is a Dump Truck?

A stand used on-road dump trucks (i.e. used tri axle dump trucks for sale) are commonly utilized in most light commercial or residential building projects. Typical capacity ranges from:

l 10-14 cubic yards per load for most standard used dump trucks for sale in the market.

l As for the weight capacity, 15-18 tons are the very normal range. However, the tonnage usually varies going with the change of moisture and soil content.

The above-mentioned 2 capacity calculation methods are quite important, as some sellers conform to the standard of cubic yards while other suppliers may do this by the weight(tons). Heavy clay weighs more than sandy fill on the density, therefore, the tonnage may vary a lot for the same volume level. When getting a quote from different suppliers, you need to verify whether their offer is based on tonnage or cubic yards.

2. What Is the Price of a Load of Dirt?

Prices vary widely by market and material, but you can make an educated estimate by considering:

l Material Grade: Simple fill dirt vs. screened topsoil or engineered/selected fill.

l Delivery Distance: Mileage, drive time, and fuel costs govern the trucking factor.

l Site Accessibility: Tight gates, soft grass, steep grades, and long reverse approaches will often entail extra charges.

l Quantity: Bulk orders may occasionally reduce the per-yard or per-ton cost.

In most worldwide locations, a delivered load of fill dirt for a small project usually ranges from mid-hundreds to around a thousand dollars, depending on accessibility and distance, with larger multi-load projects scaling up from there. The best approach is to request all-in pricing for your quantity and location, then compare vendors on the same terms.

3. Variables That Shift the Price

1) Type and Quality of Soil

l Fill dirt (extremely low organics) is the budget-friendly option for rough grading and backfill.

l Topsoil (screened, organic level) is more costly and best for surface finish layers or planting.

l Engineered/selected fill with gradation or compaction requirements is high-grade.

2) Moisture Level

Water adds weight. If it rained recently or you’re buying clay-rich soils, legal weight limits may cap what fits in a single load, changing your cost per load and sometimes requiring an extra trip.

3) Distance & Logistics

Delivery fees generally scale with mileage and expected time on site. Rural routes, congestion, bridge restrictions, or weight-posted roads can change the route (and price).

4) Quantity & Timing

A few full loads typically improve your unit economics. If you can take weekday, off-peak delivery slots, you could also experience better rates.

4. Estimating Your Yardage: How to Avoid Overpaying

a. Measure the Area: length × width × depth (in feet).

b. Calculate Cubic Yards: divide by 27.

c. Add a Compaction Factor: if you'll be compacting the fill, add ~10% to provide for settlement.

d. Cross-check By Weight If Necessary: most soils weigh about 1.1–1.3 tons per cubic yard but inquire about your supplier's exact number to ensure apples-to-apples quotes.

For Example: 40' × 25' area at 6" depth is 40 × 25 × 0.5 = 500 cubic feet. ÷ 27 ≈ 18.5 cubic yards. Round up for compaction and spillage—call it 20–21 yards, or about two standard truckloads.

5. Sample Budget Scenarios

These examples are typical. Your market may be higher or lower priced.

Driveway lift (single load):

l Scope: lift low spots across ~600–900 sq ft at 4–6" depth (≈7–12 yd³).

l Trucking: 1 standard load (10–14 yd³).

l Total: Material + one delivery fee, budget a contingency for time on site if access is limited.

Backyard grading (two loads):

l Scope: 20–24 yd³.

l Trucking: 2 loads (assuming 10–12 yd³ per load).

l Savings: Per-yard price is typically better than a single-load order.

Large pad fill (four to eight loads):

l Scope: 50–100+ yd³.

l Trucking: 4–8 loads.

l Tip: Negotiate bulk rates and schedule continuous delivery windows to keep machines and crews productive.

6. Fill Dirt vs. Topsoil vs. Specialty Mixes

l Fill Dirt: Low organic matter; most suitable for backfilling, grade raising, and sub-base construction. Cheapest; compacts well if moisture is managed.

l Topsoil: Screened and more organically enriched; intended as a finish planting layer. More expensive and not ideal for deep structural fill.

l Engineered/Selected Fill: Specified gradation or PI (plasticity index); used in structural pads, road sub-bases, and where compaction testing will most likely be required.

An economy-minded approach is to use fill dirt for mass grading and top-dress visible planted areas with 2–4 inches of topsoil.

7. Delivery Day: How to Avoid Extra Costs

l Mark dumping spot with stakes or cones, double-check area to safely dump bed.

l Protect Soft Ground: mats or plywood prevent ruts on lawns.

l Have site contact stand by to direct the driver—usually a supplier requirement.

l Stage equipment (compactor, skid steer) so spreading can immediately start and idle time can be billed.

8. Why "Cheapest Per Load" Can Cost More

Two hidden traps wipe out appearing cost savings:

l Low Loads: A rock-bottom price on a truck carrying fewer yards can drive your cost per yard higher than on a fuller, slightly pricier load.

l Turn Time: If the supplier cannot provide windows, your team waits on material—labor inefficiencies can swamp small material savings.

Watch all-in delivered cost per required yardage with guaranteed windows.

9. Choosing the Correct Truck: Single, Tandem, or Tri-Axle?

Tri-axle dump trucks carry a greater legal load than tandem or single units, reducing trips for big jobs. That's just one of the reasons contractors buy used tri axle dump trucks for sale when their annual hauling volume justifies ownership. If you run dirt on a regular basis, buying used tri axle dump trucks for sale can cut long-term costs by avoiding rental or subcontracting fees and giving you scheduling flexibility during busy season.

Used tri axle dump trucks for sale are also often standardized by fleet managers to get balance among capacity, tire types, and axle ratios—tiny improvements that save minutes per turn and dollars per yard. Across several projects, acquisition cost savings and uptime benefits from well-performing used tri axle dump trucks for sale can justify themselves while maintaining resale value if you cycle assets down the road.

10. Can You Save by Ordering Half Loads?

A half load may seem cheaper, but you’ll usually pay nearly the same delivery fee, which pushes your per-yard price up. If access is the issue, consider staging areas or multiple dump points around the site rather than splitting into inefficient partial loads. Owning used tri axle dump trucks for sale gives contractors the flexibility to right-size deliveries internally without paying retail delivery penalties.

11. DIY vs. Hiring a Hauler

With little trailers or running pickups for dirt, it looks economical until you consider time, gasoline, and wear—much less how many trips to 10–14 yards. Full-time carriers spread expenses over many hauls and know how to operate within weight limits and access restrictions. For regular haulers, purchasing used tri axle dump trucks for sale is often the better option: guaranteed supply, more control of turn times, and less all-in cost per yard on a season.

12. Comparing Quotes (Apples to Apples) - How To

Refer to this list when calling suppliers:

l Material: Fill dirt vs. screened topsoil vs. engineered/selected fill.

l Pricing Unit: Yard or ton, and conversion they use for your material.

l Truck Capacity: Yards and/or tons per truck, and any legal road capacity along the route.

l Delivery Terms: Included miles, on-site time, reschedule policy, fuel surcharge if applicable.

l Access Notes: Gate width, turn radius, overhead lines/trees, grade and soil bearing.

l Schedule: Requested time frame and on-site availability (with phone).

If your company operates used dump trucks for sale, apply the same foresight in-house—hourly fuel consumption, tires and wear items, insurance, driver wages, and overhead—so your bids are cost-based and stay competitive.

13. Frequently Asked Questions

Question 1: Is a “truckload” the same?

A: No. "Truckload" depends on truck body, local weight regulations, and material density. That's why 10–14 cubic yards will be quoted for standard on-road trucks and 15–18 tons for fill dirt. Always check with your supplier.

Question 2: Is dirt cheaper by the yard or ton?

A: Neither is necessarily cheaper. It would be dependent upon the water and density of soil. Order both units and a conversion so that you can buy "all-in delivered" prices.

Question 3: Can I mix materials in one load?

A: Typically no—composting topsoil and fill dirt in the same bed contaminates both. Make sequential deliveries instead.

Question 4: How many wheelbarrows equal one truck?

A: About a hundred average wheelbarrow loads at ~10–12 yards. Homeowner towing gets impractical for bigger jobs.

Question 5: Are weather and season factors in cost?

A: Yes. Rain or freezing slows cycles, introduces risk, and sometimes requires alternate routes or partial loads—costs can rise accordingly.

14. From Budgeting to Fleet Strategy

For housing and small crews, getting one or two delivered loads is fastest to outcomes. For earthwork and site-prep firms, investing in used tri axle dump trucks for sale strategically can transform your economics: fewer trips per job, better scheduling control, and the ability to keep equipment busy without depending on third-party haulers. If you've got used tri axle dump trucks already, you can standardize bed volumes, fit liners for clays that adhere, and optimize axle ratios for local grades—optimizing saves cycle time and lowers your per-yard cost during the season.

15. Conclusion

A truckload of dirt is 10–14 cubic yards (or 15–18 tons of fill dirt). Delivered total costs vary by soil type, distance, access, and local market conditions—small jobs are in the mid-hundreds to around a thousand dollars while large properties requiring multiple loads go up from there. Two loads for a grade in the backyard or dozens for a subdivision, the math is the same: measure carefully, confirm capacity and price units, and arrange delivery windows that keep your crew on the job. And if your company hauls a lot of soil on a consistent basis, looking into used tri axle dump trucks for sale can be the single best approach to controlling hauling schedules and costs over the long term.

If your business requires frequent hauling or you're ready to bring logistics in-house, look through our inventory of used tri axle dump trucks for sale. Our team can help you compare capacities, axle ratios, and body styles, perform cost-per-yard simulations, and secure financing—so your next dirt delivery is faster, cheaper, and entirely within your control.