Important Maintenance Tips About Dump Trucks- How To Make the Transportation RunSmoothly and Efficiently

Important Maintenance Tips About Dump Trucks – How to Make the Transportation Run Smoothly and Efficiently

Relying on their great loading capability, Dump Trucks and Used Dump Trucks have been playing an important role in the working process of construction fields, mining sites and other types of projects that need heavy-duty machinery. In most circumstances, however, these dump trucks or used dump trucks may inevitably break down during the driving course. Therefore, any issues should be found and addressed at an early date to improve the driving experience. What’s more, their lifespan can be effectively extended and lots of maintaining costs will be enormously saved. As a matter of fact, the maintenance and repair jobs are tied tightly. In a word, timely inspections and fixing operations should be done before the breakdown of worn-out truck parts. In addition, other essential components can also be maintained in a regular routine.

Keeping the Hydraulic System in Peak Working Condition

The crown jewel of any dump truck is its hydraulic system—is what easily lifts the cargo bed. If something goes amiss here, you'll want to address it sooner rather than later to prevent a domino effect of issues. Think of a seemingly innocuous issue such as a slow-lifting bed. The offenders may be abundant: low oil pressure, plugged-up filters or pipes, a bad oil pump, sticky lift switches, leaking high-pressure pumps, too little air pressure, bad PTO gears, or grimy hydraulic oil clogging the valves.

Some operators may raise an eyebrow—a single "little" issue, but so many possible culprits! That is why it is important to watch your rig closely. The golden rule: catch it early, stop the damage early. If you're catching lift issues, start with easy checks within your own competence—oil level, filter condition, lift switch operation. If that still doesn't do the trick, leave it in the hands of experts at a repair facility. Don't let a minor glitch snowball into an ugly headache.

Prevention is better than a cure. Prepare for the road by having a full hydraulic tank. Check for leaks in hoses, valves, and air lines. Do a quick lift-and-lower test with an empty bed to find out if any cylinders are stuck, there is a faulty pump, or any unusual sounds. A few minutes today can save hours—or a few thousand dollars—tomorrow.

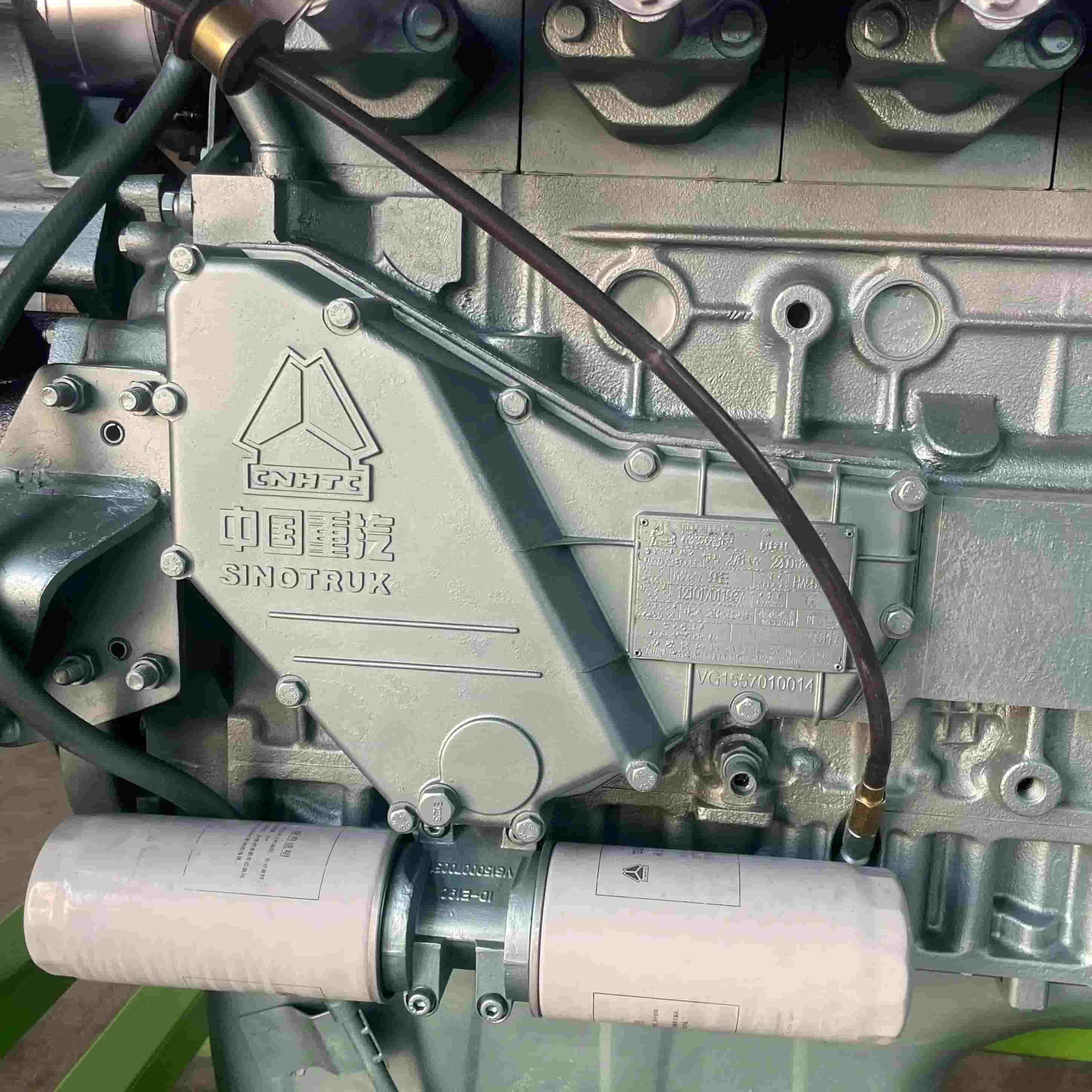

Engine Care: The Heart of the Truck

Engines need little introduction—their heartbeat for your dump truck. Clean the engine as thoroughly as possible every 5,000 km. Drain sludge and sediment to prevent thickened oil when hot, reduce wear, and keep that engine roaring strong.

Key engine care reminders:

Break-in: New or newly rebuilt, engines need a correct break-in before high-speed service

Cleanliness: Keep fuels, lubricants, air, and water free of debris, and the outside of the engine free of grime. Dirty fuel or air accelerates wear; dirty coolant clogs passages, reduces cooling efficiency, and ruins the engine.

Sufficiency: Oil, coolant, and air must be excessive. Short of this can result in starting trouble, poor combustion, or stalling of the engine.

Inspection: Regularly check bolts, nuts, and adjustment screws—they loosen with vibration and unbalanced loading.

Maintenance: Keep valve clearances, ignition timing, fuel injection pressure, and timing at peak performance levels.

Safe Use: Preheat the engine before using it for full loads, avoid prolonged overloading, and check for safe shutdown, especially in winter. Periodic inspection and timely repair keep the machine running like a horse.

Transmission and Fuel System Maintenance

Transmission requires love as well. A maintenance interval of 20,000 km is the target. Drain sludge and gummy deposits, restore O-ring and gasket suppleness, and prevent slippage, slow shifting, or overheating. Smooth power flow and linear gear shifts are the goal.

Fuel and cooling systems must be maintained too. Clean fuel valves and injectors at every 10,000 km to keep corrosion and leakage at bay. Change coolant seasonally—six-month intervals are standard—to flush sediment, prevent rust, and protect the engine from getting overheated.

Day-to-Day Use Advice for Safety and Longevity

Dump trucks have quirks that, if ignored, can turn into safety hazards. Some practice essentials include:

Inspect the truck thoroughly before every trip: tires, brakes, hydraulics, bed mounts, and fluid level.

Prior to dumping, have no one within the sides or rear. Check lift-limit devices—if broken, cease to function at once.

Following a lift, disconnect PTO and place manual valve in neutral position before traveling. Operating on a raised bed is an invitation to disaster.

Allow cargo bed to rest squarely on the subframe before driving.

Daily check alarms and limiters; respond instantly to warning indications.

Spread loads evenly—never heavily bias to one side.

Handle the PTO carefully: engage clutch first, then PTO to avoid gear clashing.

Restrict engine RPM to under 2,000 when lifting, especially over a 40° incline, in order to protect components.

Maintain open 5-meter safety zone around truck when lifting; operator stays in cab.

When servicing, always fully support bed; never work under a half-raised bed.

Additional Insights from Field Experience

On-Site Work Tips

Plan Your Routes Thoughtfully: Do not drive at random while navigating through a construction site. Consider the terrain and how the soil or material is piled up. A thought-out route prevents unnecessary U-turns, does not keep repeating the same area, and ultimately saves time and fuel. Efficiency is not just a matter of speed—it's about intelligent navigation.

Mind the Load: Always be mindful to stay within your truck's payload rating. Overloading is not just a safety risk—it can destroy your truck, causing untimely wear or even structural damage. When loading dirt, place it evenly out across the bed. An uneven load tends to cause the truck to tip over, especially on rough ground.

Clean the Bed: The cargo bed debris may appear harmless, yet they contribute to friction during dumping. Clean the bed regularly to reduce drag and make unloading a smooth operation. A clean bed is equivalent to increased cycles and a reduced load on your hydraulics.

Watch the Weather: Rainy days or muddy patches deserve extra care. Ease off, give your wheels some improved grip, and creep smoothly. Patience can pay dividends here in keeping away slips or getting stuck.

Safety and Maintenance Insights

Stay in Line with Rules: Safety isn't an option, it's a beginning. Stick with traffic regulations and operating guidelines and keep cargo secure. Maintenance is equally essential: swap worn parts, inspect hydraulic operation, and don't skip brake, tire, and fluid inspections.

Driver Training Pays Off: A professional driver is a safe driver. Invest in professional training courses to hone driving skills and stay aware of safety. Occasional drills and emergency-response training are money in the bank—they prepare drivers to react calmly and competently when the unexpected happens.

Smart use, preventive maintenance, and timely repairs make dump trucks more reliable, safer, and longer lasting. And that translates to driver peace of mind too.

For more truck tips or to find a rig that fits your needs, contact Camel Truck at +86-183 0640 8493.

Shandong Camel Truck – Your Trusted Partner