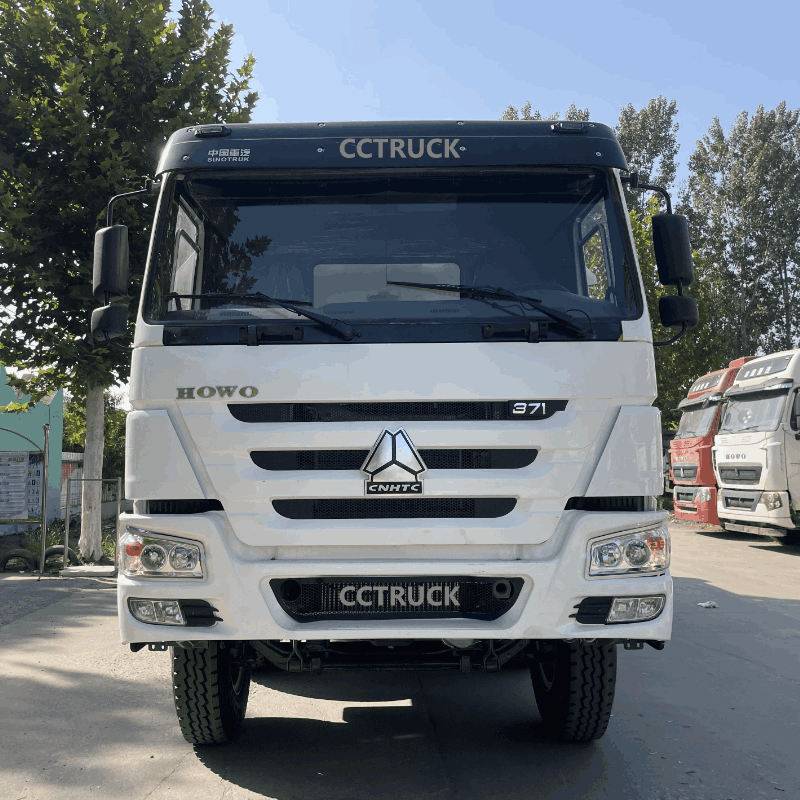

Sinotruk 12 Wheels Dump Truck

Howo 8x4 has a strong chassis and 13-ton axles, carrying over 60 tons.

It uses a 400 HP engine with a 12-speed gearbox, handling 30% slopes easily.

Reinforced springs and optimized design keep fuel use around 32–35L per 100km.

Product Introduction

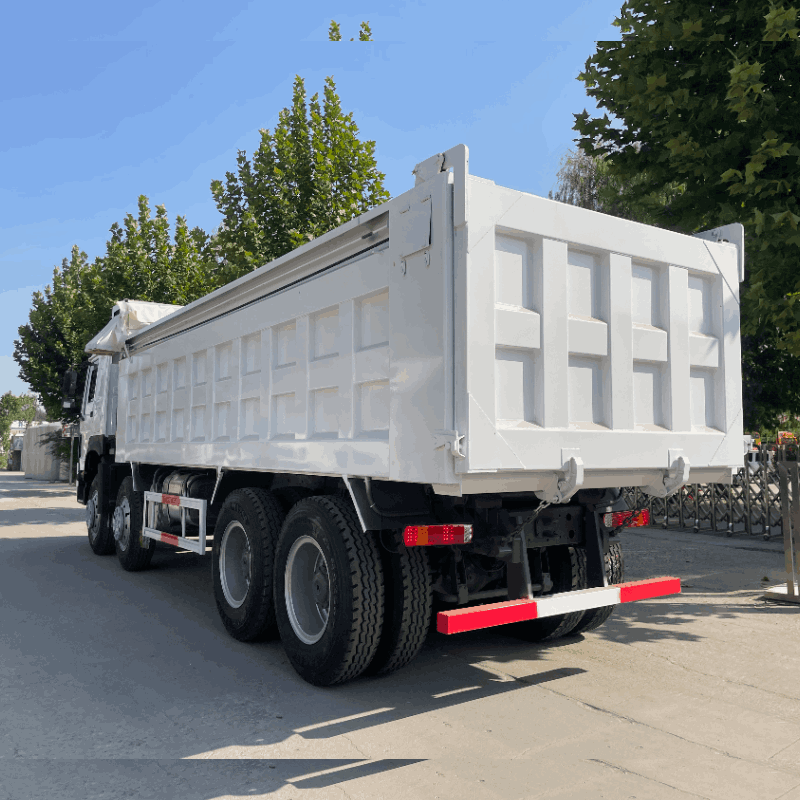

The Howo 8x4 dump truck is built for heavy-duty operations, featuring a reinforced bucket (7600mm × 2500mm × 1500mm) and 13-ton rear axles, supporting loads over 60 tons. It is powered by a Weichai WP12.400E201 engine with 400 horsepower and 1900N·m of torque, paired with a 12-speed manual gearbox for strong and smooth performance. Reinforced 7/9 leaf springs and optimized design help keep fuel consumption around 32–35L per 100km, ensuring excellent durability and efficiency. Designed for mining, construction, and large-scale earthmoving, the Howo 8x4 offers fast unloading, high stability, strong climbing ability, and reliable operation even in harsh conditions.

The Howo dump truck plays a key role in construction, mining, and large-scale earthworks. It is built to carry heavy loads of materials like soil, sand, gravel, and rocks efficiently, reducing the need for manual labor. With its robust frame, powerful engine, and high capacity, it can handle tough environments and difficult terrain. The truck’s fast unloading system boosts productivity on worksites, while its strong build ensures long-lasting performance. Whether it's moving materials on construction sites or transporting ore in mines, the Howo dump truck is a reliable and cost-effective solution for heavy-duty transport needs.

Parameter

Product Name | 8*4 Dump Truck |

new or old | used |

steering position | left |

horsepower | 371/375/420 |

Emission Standards | euro2/euro3 |

brand | |

country of origin | SHANDONG |

level | HEAVYTRUK |

Market segments | Urban..... |

engine brand | Sinotruk/weicai |

fuel | Diesel |

Displacement | >8L |

Total number of cylinders | 6 |

Gearbox brand | SINOTRUK |

Transmission type | Manual |

forward gear | 10 |

reverse gear | 2 |

maximum torque | 2500nm |

Body size | 8.6*2.5*3.4 |

Cargo size | 5.6*2.3*1.5 |

Gross vehicle weight | 12500kg |

Fuel tank capacity | 400L |

drive form | 8*4 |

passenger | 2 |

driver's seat | NORMAL |

rear camera | CAMERA |

cruise control | NORMAL |

ABS | YES |

ESC | YES |

touch screen | NONE |

multimedia system | YES |

car window | manual |

air conditioner | AUTOMATIC |

Number of tires | 10 |

TIRE | 1200R20 |

ENGINE | WD615.47 |

Driving type | Right/Left Hand Driving |

Transmission | HW19710 Manual Transmission |

Chassis brand | SINOTRUK HOWO Chassis |

Cab | HW76 with AC One sleeper |

load capacity | 50-60t |

Factory introduction

Shandong Camel Automobile Co., Ltd. is located in Liangshan, Shandong, China's largest second-hand truck trading base and China's largest special vehicle production base. The company was established in July 2019 and is a pilot enterprise for second-hand car export approved by the Ministry of Commerce. Relying on the rich local industrial resources and policy support for rapid development, it has now become a benchmark enterprise in the field of domestic second-hand car preparation and sales and special vehicle manufacturing and sales, and enjoys an excellent market reputation.

1. Professional team: There are nearly 100 people, including more than 40 automobile maintenance and preparation technicians, more than 60 sales staff, etc.

2. Modern factory: covers an area of about 25,000 square meters, equipped with domestic first-class production lines, integrating production, storage, repair, maintenance and maintenance functions.

3. Production capacity: 3,000 second-hand trucks of various types are prepared annually, covering tractors, dump trucks, cement mixers, buses and other models.

Rebuild engine

Complete Engine Disassembly: Disassembling the engine helps assess its condition and plan targeted maintenance.

Parts Replacement: Remove parts worn over 20%, distinguish them from good parts, and prepare new replacements.

Cleaning: Parts are cleaned using industrial infrasonic waves to clear oil passages, carbon deposits, and sand scale. This makes it easier to identify worn parts for elimination.

Sorting and Polishing: After cleaning, sort parts, discard worn ones, and polish the good ones to remove rust. Replace all discarded parts with new ones.

Reassembly: Reassemble the engine following strict procedures, similar to new engine assembly. This includes sealing methods, precise torque settings, and cleaning all parts to maintain performance.

Testing:

Oil Pump Testing: Use advanced machines to test oil pump fuel injection volume and pressure.

Injection Calibration: Adjust injection volume and pressure for consistency.

Optimization: Fine-tune the engine for stable power output.

Load Testing and Data Analysis:

Load Simulation: Test engine performance under different loads.

Data Analysis: Measure power, torque, RPM, and temperatures.

Leak Detection: Inspect for oil leaks.