Used Sinotruk Howo Dump Truck 8x4

Heavy-duty 8×4 driveline with hub-reduction axles for steady traction on rough haul roads

Reinforced ladder frame and rock/earth body options (8/6 mm or 12/10 mm) for long service life

Front-lift hydraulic hoist for quick, stable tipping and cleaner beds between cycles

HW76 cab with A/C, clear sightlines, and simple controls to keep drivers consistent on long shifts

Global HOWO parts support and straightforward maintenance to reduce downtime and cost per ton

Moving a lot of material in a short window isn’t about fancy slogans. It’s about a truck that starts every morning, climbs the haul road without fuss, tips cleanly, and heads back for the next load. The Sinotruk Howo 8×4 Dump Truck has earned that reputation on quarry floors, mine benches, highway embankments, and city excavation sites. It puts a strong chassis under a straightforward driveline and a steel body that’s built to take a beating. Drivers like the simple cab and good visibility. Mechanics like the access. Managers like the numbers at the end of the shift.

What you can expect on a real job

Picture a typical day on a quarry run: short shuttle from the face to the crusher, rough underfoot after overnight rain, loaders queuing to keep the plant fed. The Howo 8×4 settles into a rhythm. Launch is steady, even when the ramp is slick. Ratios are spaced so the driver isn’t hunting for gears every few seconds. The front-lift hoist sends the body up quickly at the hopper; aggregate clears without hanging on the floor. Tailgate hardware closes square, and the truck is already lining up for the loader by the time the next unit reaches the tip. That consistency is where output comes from—not big claims on paper, but minute-by-minute behavior you can count on.

Frame, axles, and body: the parts that take the punishment

The chassis uses reinforced ladder rails with cold-riveted cross-members. It’s a simple recipe that resists twist and shock when one side of the truck drops into a rut. Up front, HF-series axles keep steering precise under load; at the rear, hub-reduction drive axles let the truck put torque to the ground without abusing the final drive. Springs are heavy multi-leaf packs with stout pins and hangers. Nothing exotic, just parts that last.

Bodies are specified to match material. For soils and sand, most fleets choose an 8/6 mm (floor/side) build to save weight and fuel. For blasted rock or oversized stone, the common upgrade is 12/10 mm with optional wear liners. Side height and length combinations typically land you around 22–26 m³ usable capacity. The front-mounted hoist keeps the body stable as it rises; cycle times stay sharp and operators don’t fight “carryback.”

Powertrains that crews already know

You’ll see two engine patterns again and again in export builds. The 371 hp option is a favorite for simple, rugged service. Where climbs are longer or altitude is a factor, the 420 hp setup gives extra pull without complicating maintenance. Both pair well with the HW19710 10-speed manual. The point is not chasing top-end speed; it’s keeping the engine in the meat of the torque while you crawl, turn, and tip all day long. Parts for these combos are everywhere, and most workshops can diagnose them without special tools.

Why drivers stay steady in this cab

The HW76 cab isn’t a showpiece; it’s a decent place to work. Air conditioning that holds up in hot weather, a seat that supports the lower back, clear analog dials, and switches where you expect them. Visibility is good around the A-pillars, and mirrors are sized for real blind-spot coverage. After ten or twelve hours, that matters more than any brochure line. A calmer driver makes fewer mistakes and wastes less time between the loader and the hopper.

Where it earns its keep

Quarries and open pits: overburden, ore, and aggregate moves between face, crusher, and stockpile.

Civil works: highway fills, platform build-ups, flood protection projects.

Urban excavation: muck-away and materials transfer on private haul roads.

Plant logistics: short transfers between screens, bins, and stock areas.

These are short-to-medium routes, often with broken ground, tight turns, and stop-start flow. That’s exactly what the Howo 8×4 is set up for.

Maintenance without drama

Most service items are right where you want them. Air and fuel filters sit clear of hot zones. Access around the gearbox is workable, and the hub-reduction rears are laid out sensibly. Air lines are routed to avoid chafe points. Electrical connectors are easy to trace. The truck doesn’t demand a dealer visit for every little thing, which means fewer long stoppages waiting on a laptop or a specialist.

Stocking the basics goes a long way: filter sets, pads/linings, belts, bulbs, a small selection of hoses, and a pair of hub seals. Many fleets keep a spare tyre and a tailgate hinge kit on hand. None of this is costly, and it keeps the unit in rotation when the site is busy.

Body choices and how to pick

Rock work: Go with 12/10 mm floor/sides and consider liner plates if the stone is sharp or you’re dumping over a steel wear edge. You’ll carry a little more tare, but the floor will last and the side walls won’t oil-can after a few months.

Soil and sand: 8/6 mm saves weight. The truck feels livelier, and fuel burn comes down. If you occasionally handle rock, fit protective strips at the tail and keep an eye on the floor.

Side height: Don’t chase maximum cubic meters at all costs. Match to density. If you routinely push past legal gross, you’ll lose time to enforcement and break things you didn’t plan to replace.

Tyres and ratios

12.00R20 is the safe, widely stocked choice and works well off-road. If your region carries 315/80R22.5 at better prices or you prefer radial options for mixed routes, that size is supported too. On ratios, be honest about your ramps. A conservative final drive with hub reduction and a patient driver often moves more material per shift than a “fast” setup that needs constant downshifts and overheats on climbs.

What we check before it leaves us

Powertrain: start, idle, smoke, leaks; cooling circuit; clutch take-up; shift quality; road test with hub temperature checks.

Chassis and body: frame straightness; spring packs and bushings; hoist full-stroke test under ballast; tailgate latch and hinge condition; floor and side wall survey.

Brakes and electrics: air leak-down and balance; reverse alarm, work lights, beacons; HVAC performance; belts and mounts.

You’ll receive photos and a short video of the exact unit. Third-party inspection can be arranged. A small starter kit of consumables ships with the truck if you want to hit the ground running.

Day-to-day behavior that protects your cost per ton

Clean dumps: fewer shovels in the back of the bed and no nudging with the loader.

Calm climbs: torque where you need it, without gear hunting.

Straight tracks: frame that doesn’t twist itself to pieces after a month of potholes.

Simple fixes: if something does act up, it’s usually an hour in the bay, not a week waiting on parts.

Common questions, straight answers

Is 371 hp enough?

For most quarries and earthworks, yes—if you choose the right ratio and drive with some feel. If you see long grades at altitude or you’re habitually at the top of gross, the 420 hp option gives breathing room.

How big should the body be?

Aim for the capacity that keeps you legal on the routes you travel and matches your material. Many fleets settle around 7.0–7.6 m length and 1.5 m sides, then switch thickness and liners by site.

What about left- or right-hand drive?

Both are available for export builds; we confirm at the quote stage.

How fast after delivery can it work?

With the checks above and a brief handover, trucks usually go straight to loading. On arrival we can help run through fasteners, fluids, hoist timing, and brake balance.

Spec snapshot (reference, verified per unit)

| Item | Specification |

|---|---|

| Drive | 8×4 (12 wheels) |

| Engine (typical) | 371 hp or 420 hp diesel, by market |

| Transmission | HW19710 manual, 10F/2R |

| Front / rear axles | HF-series front / AC16 or HC16 rear, hub-reduction |

| Tyres | 12.00R20 (315/80R22.5 optional), 12 + 1 spare |

| Fuel tank | ~300 L |

| Dump body | ~7000–7600 × 2300 × 1500 mm |

| Plate thickness | 8/6 mm (earth) or 12/10 mm (rock) |

| Usable volume | ~22–26 m³ (by body) |

| Overall dimensions | ~11,145 × 2,496 × 3,450 mm (varies with body/tyres) |

| Wheelbase | ~1,800 + 4,600 + 1,350 mm |

| GVW (typical) | up to ~31,000 kg, market dependent |

Figures change with emission tier, side height, tyres, and local rules. We confirm the exact build sheet, photos, and video for the unit you pick.

Buying notes that save headaches

Share three things up front: dominant material (rock or earth), steepest grade on the route, and target body volume. With that, we’ll steer you to the right body thickness, axle ratio, and tyre set. If you’re standardizing a batch for a project, we’ll align the wheelbases, ratios, and bodies so the fleet behaves the same across different crews and sites. That keeps training short, simplifies spares, and makes rotation easier when a truck needs scheduled service.

Tell us where you’ll run the trucks and what you’re hauling most of the time. We’ll send a short list of Sinotruk Howo 8×4 Dump Trucks available now, with walk-around videos, inspection sheets, tyre condition, and FOB/CIF pricing to your nearest port. From there, it’s simple: pick your unit(s), confirm the body and ratio, and get them working.

About Us / Camel Truck

Shandong Camel Truck Co., Ltd. is located in Liangshan, Shandong, China – the largest used truck trading hub in the world. Founded in August 2010, the company has nearly 300 employees, including over 200 professional technicians. Our modern factory covers 25,000 m² and features top-class production lines, with the capacity to stock, maintain, refurbish, and repair over 3,000 trucks annually.

We supply trucks and parts from brands including HOWO, Shacman, Volvo, Mercedes-Benz, Beiben, covering dump trucks, tractor trucks, semi-trailers, mixers, and specialized vehicles. Our one-stop services include inspection, transportation, customs clearance, and after-sales support. Our sales network spans Africa, Central Asia, Southeast Asia, and more than 50 countries. In 2024, our sales revenue reached 100 million USD.

Since our establishment, we have upheld the corporate spirit of "Integrity First, Quality First, Service First," leveraging local resources and policy support to become a leader in China’s used truck industry, building "CAMEL TRUCK" into a globally recognized brand for used trucks, new trailers, and parts.

Truck Refurbishment & Services

Mechanical Maintenance & Overhaul: Thoroughly inspect engines, gearboxes, and axles, replace oils and filters.

Exterior Refurbishment: Repaint chassis, body, cabin, and rims to restore new look.

Component Upgrade: Replace critical parts (battery, fuel tank, wiring, air system) and update the AC system.

Cabin Renewal: Install new seats, sleeper, dashboard, and interior for comfort.

Final Polishing: Wax before shipment for shiny, clean surface.

Engine Remanufacturing: Use advanced equipment for full inspection and performance testing with reports to ensure reliability.

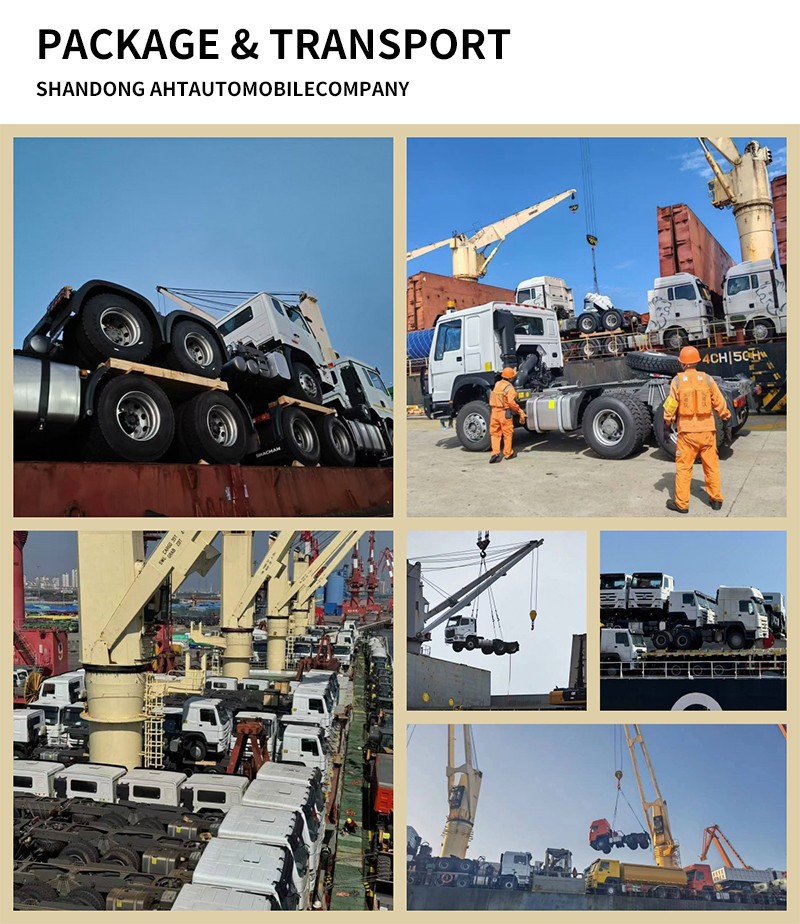

On-time Delivery: Partner with international shipping lines and freight forwarders to ensure safe, timely delivery.

Applications

Mining Transport

Dump Truck: High load capacity for sand, gravel, and ore. Tractor Truck: Transport large mining equipment and materials.

Construction Sites

Dump Truck: Transport large volumes of earth and construction materials. Tractor Truck: Haul concrete mixers or construction supplies.

Logistics & Freight

Dump Truck: Short-distance or regional bulk material transport. Tractor Truck: Long-distance container or freight transport.

Port Shipping

We ship year-round from major ports including Qingdao, Tianjin, and Shanghai. All trucks are fully inspected and tested before shipping to ensure customers receive vehicles in excellent condition.

Certificates & Awards

Our company is ISO certified and has long-term partnerships with international logistics and mining companies, proving our export capabilities and industry recognition.

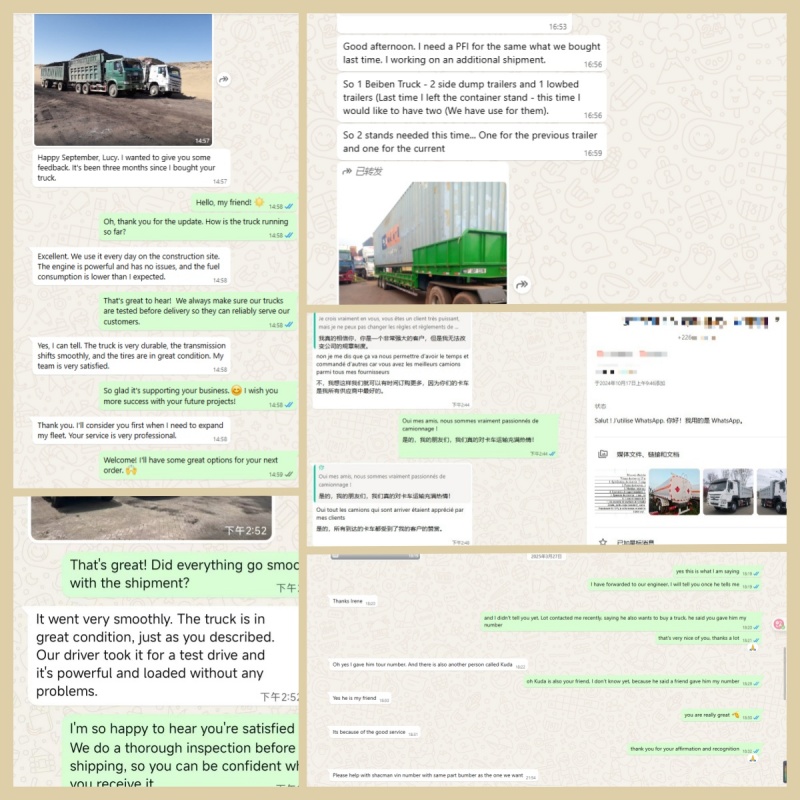

Customer Reviews

Below are authentic feedback from our customers. Our high-quality service has earned their trust, leading to long-term cooperation. Our professional design team also provides suitable customization plans and after-sales support, ensuring every customer receives excellent service.

Factory & Workshop

Our modern factory and workshop are equipped with advanced production lines and refurbishment facilities. We specialize in inspecting, maintaining, and refurbishing HOWO & Shacman dump trucks and tractor trucks, ensuring top-quality performance and reliability for all our vehicles.

Frequently Asked Questions

Q1: What payment methods do you accept?

A: We support T/T (30% deposit + 70% balance), L/C, and third-party escrow payments to ensure secure transactions.

Q2: How long does it take to ship?

A: Usually within 7–15 days after payment confirmation, depending on ports and shipping routes.

Q3: Do you provide warranty and after-sales service?

A: Basic warranty for engines and major components is provided. We also offer long-term OEM spare parts and remote technical guidance to ensure worry-free use.

Q4: Can we customize configurations?

A: Yes, we offer emission standards adjustment, cabin upgrades, tire selection, and other customization services. Contact our sales team for a quote.

Q5: What applications are dump trucks and tractor trucks suitable for?

A: Dump trucks are ideal for mines and construction sites, while tractor trucks are suitable for long-distance logistics, container transport, and heavy equipment hauling. Both are professionally refurbished for harsh conditions.